- Home

- Knowledge Hub

- News

- Scott Bader highlights industrial additive...

Scott Bader highlights industrial additive manufacturing capabilities at Formnext 2025

09/10/2025

Ben Penney

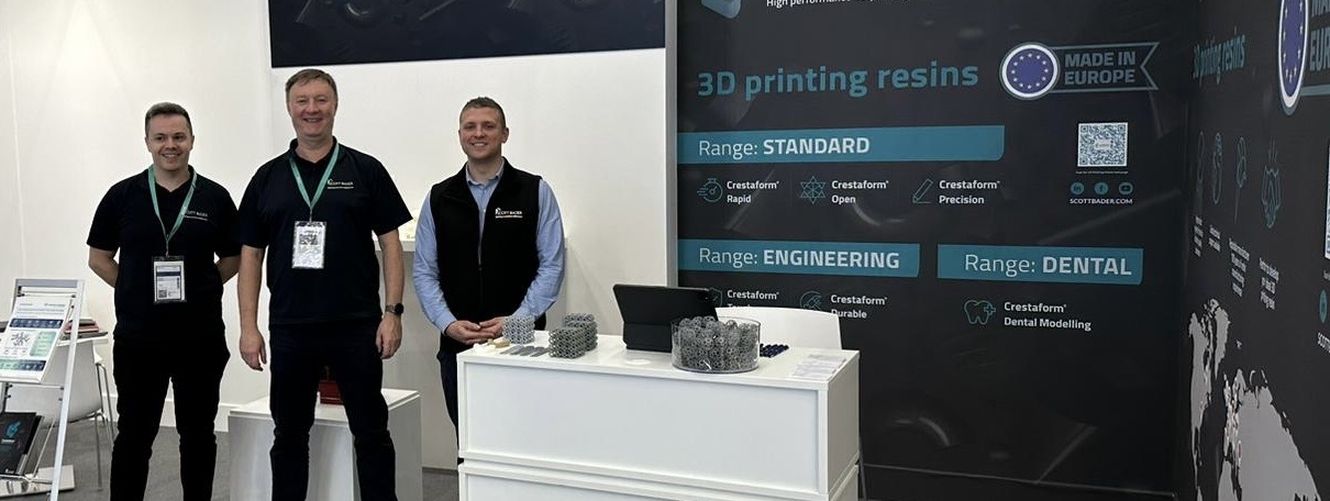

Formnext is the global flagship event for additive manufacturing and next-generation industrial production. Each year it brings together engineers, designers, OEM’s and material innovators to accelerate industrial 3D printing from prototype to production.

Scott Bader is pleased to confirm its participation at Formnext 2025, marking this an important strategic moment to connect with partners, showcase materials expertise and demonstrate how high-performing chemistry unlocks real business outcomes in additive manufacturing.

Why Attend Formnext To See Scott Bader

Formnext is held in Frankfurt and in 2024 it featured 860 exhibitors in and 34,400 attendees overall, of which 38% visitors attend this and no other trade show in this sector. The show attracts a diverse audience: production engineers, material scientists, product designers and supply chain decision makers. For companies exploring industrial 3D printing, whether for tooling, functional end-use parts or composite structures – the show is where technology, business and community merge.

Scott Bader’s presence at Formnext is being driven by the same objective every forward-looking manufacturer share: moving additive manufacturing beyond prototyping and into reliable, scalable production. By offering UK-manufactured resins compatible with a wide range of printers, Scott Bader makes it possible to achieve consistent and efficient production of higher quality parts. Combining material science, formulation capability and application support, we meet the mechanical and regulatory needs that production AM demands—while giving you the flexibility to choose the right printer for your setup. Visit our stand to engage with technical experts who understand the full cycle – from resin choice and composite reinforcement to post-processing and part performance.

Stand 12.1 | B118 | Frankfurt am Main

What Scott Bader Will Showcase

Attendees can expect a focused presentation of materials and processes tailored to industrial and dental additive manufacturing (AM). Highlights will include high-performance polymer and resin systems formulated for stereolithography (SLA), digital light processing (DLP) and other photopolymer routes.

Crestaform3D Rapid - General-purpose, fast, high-resolution resin designed for rapid prototyping on UV LCD and DLP systems. Optimised for quick print speeds and high reactivity to increase throughput during prototype and small batch runs.

Crestaform3D Tough / Durable - ABS-like performance with reduced crack propagation; combines strength, stiffness and resilience for functional/engineering parts and higher-stress applications. Suited to customers targeting end-use components or robust prototypes.

Crestaform3D Flex – Formulated with high tear strength, more tensile strength, better elongation and less cracking after repeated use. Designed to simulate the flexibility of rubber or TPU, to withstand bending, flexing and compression.

Prototypes will demonstrate how Scott Bader’s formulations translate into measurable benefits: improved dimensional stability, reduced processing costs, and enhanced end-use performance. The display will include real-world parts produced for multiple sectors (for example, marine) and functional components that integrate with our broader product range, such as adhesives and gelcoats. Unlike distant suppliers, Scott Bader offers guided support as you adopt Additive Manufacturing, providing tailored solutions to meet your needs without requiring large capital commitments. We will demonstrate throughput and reliability improvements achievable with the right material system and show how our materials can be implemented easily within existing workflows rather than treated as standalone solutions. Example parts include a cable management system with bonded metal fixtures and high-performance white and coloured gelcoat finishes to illustrate a lower-cost, high-quality surface on printed components.

Pushing The Boundaries of Manufacturing

Scott Bader is committed to advancing next-generation manufacturing through sustained investment in formulation science, collaborative application development and sustainability. Our approach is pragmatic and outcomes-drive: partner with customers to define performance criteria, iterate material systems with R&D and validate on production platforms. Sustainability is woven into this process by optimising formulations for energy efficiency in processing, longer life of a part and material reuse, recyclability and biodegradability where feasible.

Collaboration is central to our approach. We work with OEMs, service centres and end users to close the gap between material capability and industrial requirements. Our materials are formulated to be compatible with a wide range of UV LCD and DLP printers that accept third-party resins, giving customers choice when selecting their AM setup. We also collaborate with authorised printer distributors who can provide guidance throughout the adoption process. This collaborative model is how Scott Bader’s additive manufacturing solutions move from occasional prototyping into predictable, production-grade applications.

Visit Us At Formnext 2025

Stand 12.1 | B118 | Frankfurt am Main

We invite vistors to meet our R&D team, business managers and application specialists at Formnext:

Tom Kugelstadt - Head of Technical Support + Business Manager 3D Printing

Szymon Przybylak – 3D Printing Technology Manager

Benjamin Bowles – 3D Printing Senior Application Chemist

Sanjay Kumar – 3D Printing Application Chemist

Formal meeting slots and technical deep dives will be available – please reach out to us directly or book via Formnext app to reserve a time.

About Scott Bader In Additive Manufacturing

Scott Bader has built a reputation in polymer chemistry and composite solutions that translate effectively into additive manufacturing opportunities. Chemistry is at the heart of everyday life, and this is where you’ll find Scott Bader. Since 1921, we have been delivering the quality products and services our customers need and today, we continue to drive even better standards in chemistry on a global scale, building a more sustainable future for everyone. What sets us apart is our commitment to making a positive difference: it’s not just our tagline, it’s how we do business. In line with our purpose, we are committed to setting the standard in sustainable chemistry so that people and the planet can thrive in harmony.

Our experience spans formulation, composite reinforcement strategies and collaborative problem solving with manufacturing partners and capabilities critical to moving AM deployments from laboratory developments into reliable factory processes. Make our difference your advantage. For technical teams seeking reference cases and product information, please access our products page, our knowledge hub, and the news section for recent papers. These resources provide deeper insight into validated applications, technical data, and the support available from our teams.

Mentioned products

Find below a list of products mentioned within this article:

!["Modern high-speed train in motion with sleek exterior design utilizing Scott Bader composites for lightweight transportation applications" [G]](https://a.storyblok.com/f/329344/8333x3125/a61b70e4f7/sb_website_markets_land_transport_2000px.jpg/m/320x400)

Markets & Products

Manufacturing materials that are behind many big, successful brands, creating products that people rely on, every day.

!["Industrial manufacturing equipment processing composite materials for Scott Bader structural adhesives production" [G]](https://a.storyblok.com/f/329344/3737x2927/a75a9479c3/scott-bader-am-sla-print.jpeg/m/320x400)

Your guide to additive manufacturing

Additive manufacturing is a process of creating three dimensional objects from digital designs, typically building them layer-by-layer.

!["Pouring green Scott Bader resin into manufacturing equipment for composite production process" [G]](https://a.storyblok.com/f/329344/6000x4000/67b4429d3e/scott-bader-additive-manufacturing-resin-bottle.jpeg/m/320x400)

The advantages of additive manufacturing resins

Additive manufacturing is transforming industry, enhancing performance and cutting costs by producing parts faster, cheaper, lighter and more sustainably.

!["Laboratory technician using specialized equipment for testing Scott Bader resins and composites for quality control" [G]](https://a.storyblok.com/f/329344/800x533/b7b232e77c/scott-bader-dental-am-printing.jpg/m/320x400)

Dental additive manufacturing resins

Additive manufacturing has become a transformative technology within the dental industry, driven by increasing demand for patient-specific solutions, improved turnaround times and cost efficiency.