- Home

- Markets Products

- Building Construction

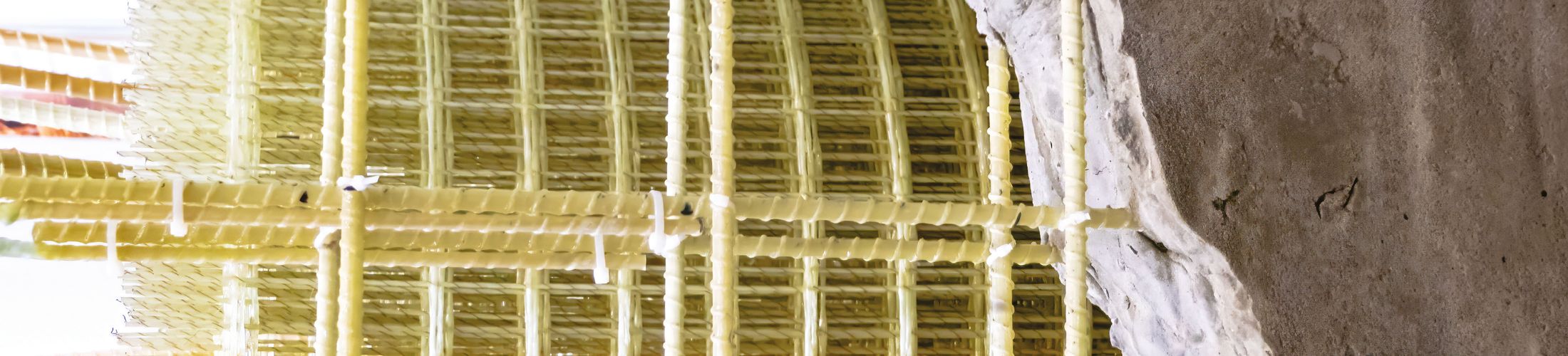

- Fiberglass Rebar

Fiberglass Rebar

The best way for fiberglass rebar manufacturers to produce durable, corrosion resistant rebar. Scott Bader makes producing fiberglass rebar energy efficient and cost effective with proven corrosion resistance, advanced curing flexibility and high line speeds – all based on our world-renowned vinyl ester technology.

For over 70 years Scott Bader has been developing and manufacturing vinyl ester, urethane acrylate and isophthalic resins for pultrusion and rebar applications.

Why Choose Fiberglass Rebar Over Steel?

Traditional steel rebar faces challenges like corrosion, weight and magnetic interference. Fiberglass rebar offers significant advantages compared to steel:

Corrosion Resistance: Fiberglass rebar is inherently resistant to rust and chemical degradation, extending the lifespan of concrete structures in tough environments. This is a critical factor for infrastructure development around the world.

Lightweight Construction: Lightweight fiberglass rebar ensures lower transportation and handling costs, as well as lighter-weight final structures.

Non-Conductive Properties: Fiberglass rebar is not susceptible to electromagnetic interference, making it ideal for specialised applications such as electrical substations.

High Tensile Strength: Fiberglass rebar provides comparable or superior tensile strength to steel, ensuring the structural integrity of reinforced concrete.

Scott Bader's High Performance Vinyl Ester Technology

Crystic VE671 is a premium vinyl ester resin engineered for high-performance rebar applications. Renowned for its exceptional curing properties and superior durability, Crystic VE671 stands as the resin of choice for industry professionals seeking high-performance, reliability and efficiency.

Advanced Curing Capabilities: Crystic VE671 is designed to cure effectively with industry-standard hot moulding catalysts. These catalysts are optimal for the pultrusion process, providing flexibility and efficiency in the manufacturing process.

Catalyst Flexibility: The curing temperatures and catalyst ratios of Crystic VE671 are flexible. Lower catalyst ratios necessitate higher curing temperatures, whilst higher catalyst ratios enable lower curing temperatures, offering flexible processing vs Epoxy.

Optimised Manufacturing Efficiency: Crystic VE671 can achieve typical line speeds of 3.5 meters per minute (mpm) with oven temperatures ranging from 150°C to 200°C. This efficiency ensures a streamlined production process, maximising output and reducing downtime.

Energy Efficiency: Crystic VE671 is more energy efficient compared with epoxys, providing significant value in terms of life cycle costs and a lower environmental footprint.

Corrosion Resistance: Extensive research has shown our high quality Crystic VE671 vinyl ester technology offers superior corrosion resistance when compared with other resin technologies, particularly in alkaline concrete environments. This characteristic is critical for end users focusing on long-term durability and life cycle performance.

Proven Performance: Crystic VE671 has undergone rigorous testing to ensure long-term durability. Industry leaders have set high standards, and Crystic VE671 has successfully met and exceeded these stringent criteria.